The vehicle group of multinational power management company Eaton has announced the launch of a new metal 3D printing program as part of its Industry 4.0 strategy.

The company aims to reduce production times and improve efficiency through its new 3D printing capabilities, and will look to deploy the 3D polymer printing technology globally by the first quarter of 2021. Meanwhile, the first metal printer system has already been installed at Eaton’s Kings Mountain facility in North Carolina.

Eaton and 3D printing

Posting revenues of $21.4 billion in 2019, Eaton employs some 92,000 employees and has a global customer base that spans more than 175 countries. The firm has already integrated 3D printing into a number of areas across its business.

In 2018, its aerospace division purchased two Concept laser additive manufacturing systems from GE Additive, to be integrated into Eaton’s Additive Manufacturing Center of Excellence at its Innovation Center in Southfield, Michigan, and its research and development (R&D) lab in Pune, India. Two years after its establishment in 2016, Eaton’s Michigan facility earned AS9100 Rev D certification, validating its quality system for the provision of safe and reliable metal 3D printed aerospace products to civil and military customers.

Since then, Eaton has used additive manufacturing to generate low-cost hydropower for the U.S. Department of Energy, through the manufacture of hydropower turbines and generator sets. The company also recognized 3D printing as a valuable method in achieving its Zero Waste to Landfill (ZWTL) initiative across a number of its sites.

Most recently, Eaton partnered with the Lighting Research Center (LRC) in Troy, New York, to develop a fully 3D printed LED-integrated luminaire. Backed by the Department of Energy, the project aimed to overcome the barriers to the adoption of additive manufacturing technology within solid-state lighting (SSL).

Eaton’s new metal 3D printing program

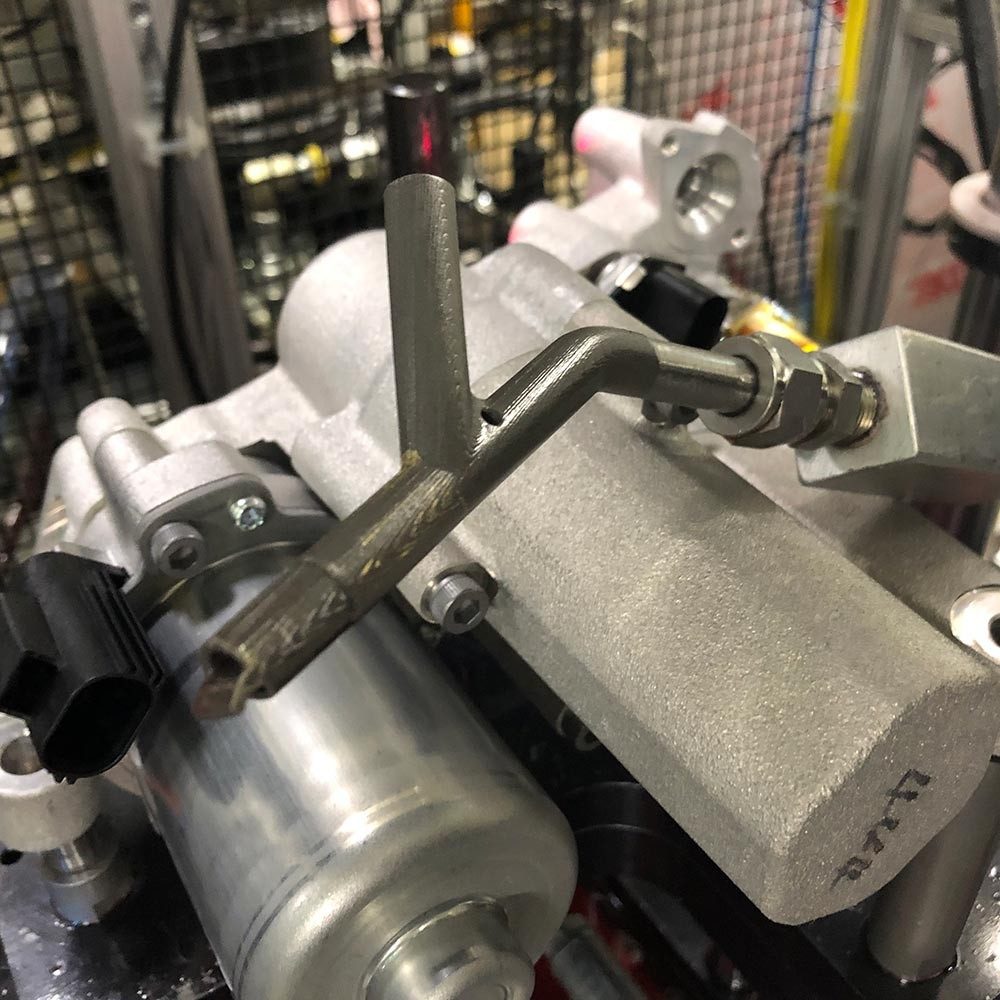

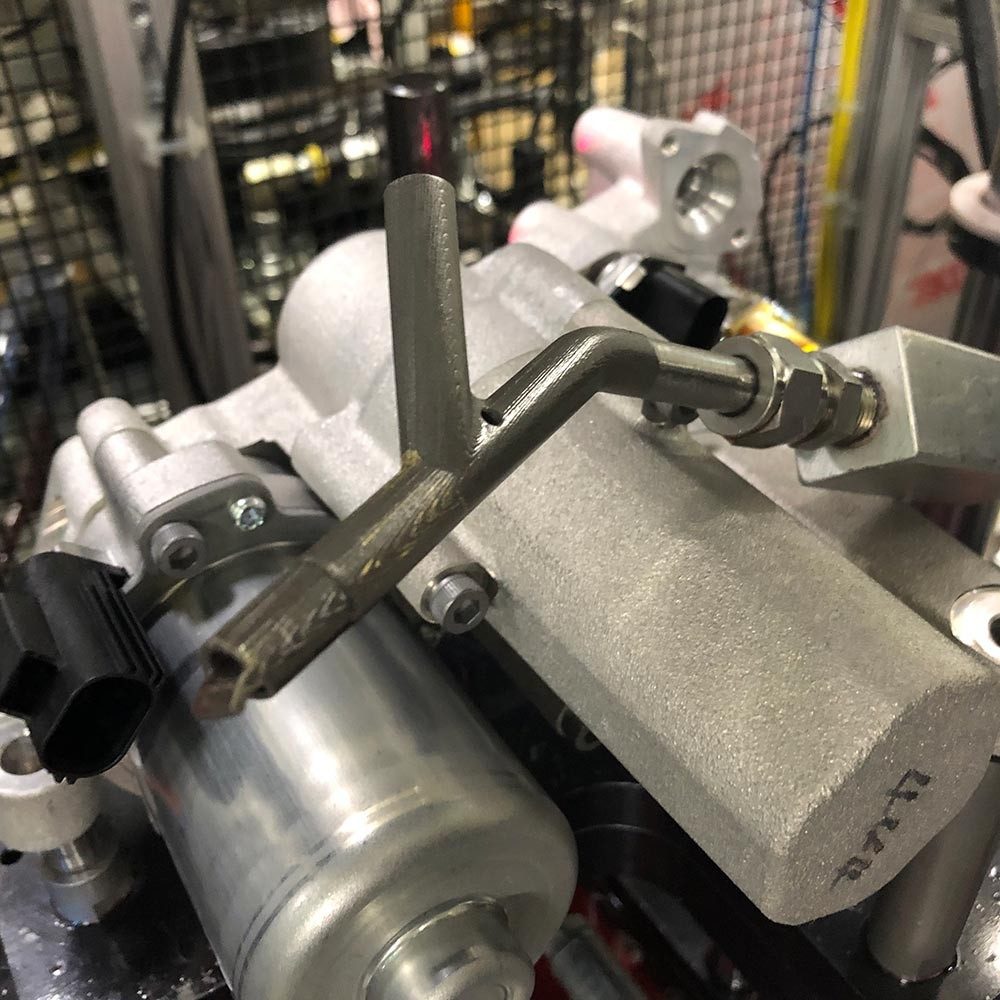

Within Eaton’s latest program, the 3D printers will be used to create high-quality automotive fixtures, safety devices, automation grippers, and maintenance components that need replacing. The printers will also be used to develop prototypes to aid faster product development trials.

Eaton hasn’t revealed what metal printers it will be using, but it has described the extrusion-based printing process they will use. Powdered metal stored in a rod and held together by wax and a polymer binder will be melted and added layer by layer. Once the printing process is complete, the part will be run through a chemical bath to remove the polymer binder and then passed through a furnace to remove any remaining wax and polymer. This process will simultaneously fuse the metal material in a high-density structure.

The debinding and heat treatment processes are completed in batches. According to Eaton, although the printer, debinding, and furnace work together in an integrated loop, the number of printers can be increased without having to adjust the number of debinding stations or furnaces.

Throughout the design process, 3D scanners will be used to create models of existing components and re-engineer parts that can be improved through 3D printing. Through this, topology optimization, material reduction, and part consolidation can be facilitated.

Integrating 3D printing will allow Eaton’s Vehicle Group to realize more advanced designs while reducing the amount of post-processing stages and lowering material costs. Looking ahead, Eaton’s Vehicle Group will utilize its 3D printing capabilities to drive down production times and improve efficiency across its processes.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Eaton’s Vehicle Group reduced cost and development time using its 3D metal printing capabilities to produce this oil fill nozzle. Image via Eaton.