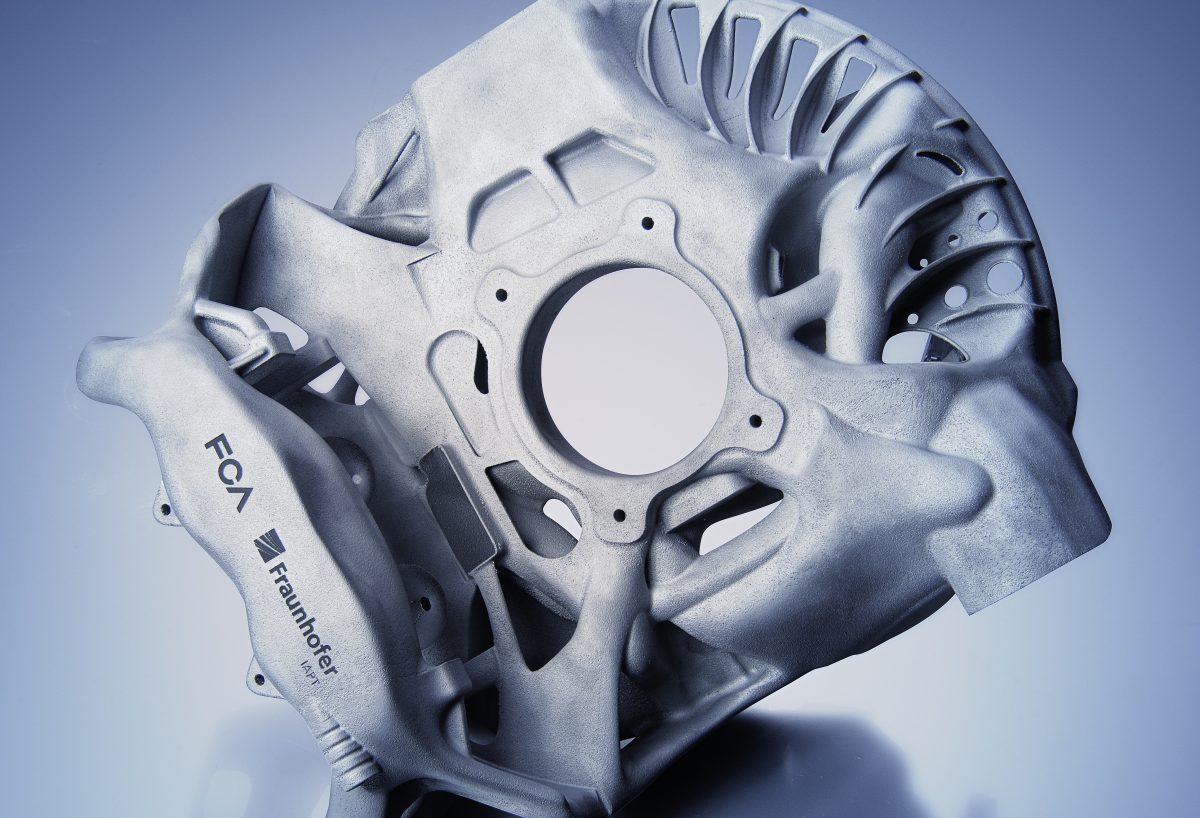

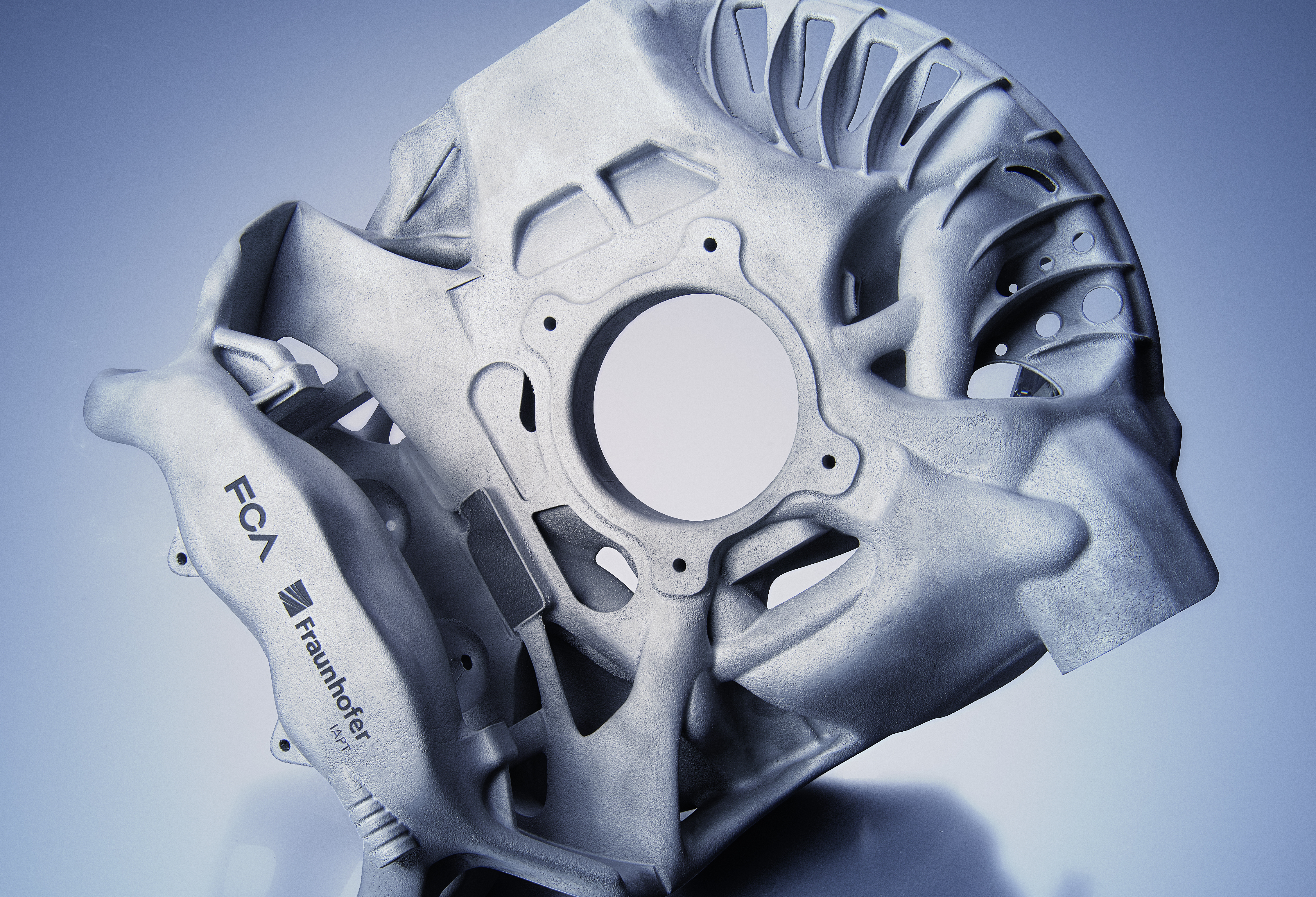

Researchers from the Fraunhofer Research Institution for Additive Manufacturing Technologies (IAPT) have worked with engineers from Fiat Chrysler Automobiles (FCA) to develop a 3D printed suspension part for one of its sports cars.

Using additive manufacturing, the joint team was able to integrate the vehicle’s brake caliper into its wheel carrier, while making it 36 percent lighter and more fatigue resistant. Given that reducing the brake system’s constituent parts was found to cut down its associated costs and lead times, it could represent the FCA group’s first step towards the serial 3D printing of vehicle components.

“Together with our innovation partner Fraunhofer IAPT, we are cutting the costs and production effort for key vehicle parts,” said Carlo Carcioffi, Head of Advanced Processes at FCA. “The knowledge transfer will help us to improve additive manufacturing competence in the fields of integrated design, materials, and process technology across the group.”

The Fraunhofer-Fiat-Chrysler research project

The engineers embarked on their research with the ambition of 3D printing and optimizing an entire end-use suspension system for an unspecified FCA sports car. Although neither group revealed the model that they had been working on, it could be for one of several historic supercar brands within the FCA group’s portfolio, which includes Maserati, Lancia, and Alfa Romeo.

At present, the suspension system in question consists of twelve separate components, including a wheel carrier, brake caliper, hydraulics, and heat shield. Manufacturing these parts individually before assembling them using screws, seals, and washers is currently a complex, time-consuming, and expensive process.

Consequently, the joint team sought to reduce the number of steps involved in producing the part, by condensing its functions into a singular unit. As IAPT Design Engineer Yanik Senkel explains though, developing a 3D printed suspension system to match the high demands required by FCA, proved to be a challenging task.

“We had, together with the FCA design team, to completely rethink the entire wheel suspension,” explained Senkel, “in order to achieve a one-piece bionic structure that fulfilled all the functions of the previous assembly at least equally as well, absorbed all the forces, was weight-optimized and could be produced additively.”

FCA’s additive sports car ambitions

Using topology optimization, the engineering team developed a prototype system that combined the conventional part’s twelve components into one consolidated unit. The resulting bionically enhanced design weighs 36 percent less than the original and features enhanced fatigue strength, thanks to its more robust construction.

Due to the part’s impact-resistant qualities, the team also speculated that it would perform better than the original in terms of noise, vibration, and harshness (NVH), a vital part of the luxury sportscar experience. What’s more, by addressing the current suspension’s weak points, the engineers believe that their additive part could last longer, reducing the inconveniences associated with servicing.

Although the enhanced component has obvious end-use advantages, according to Fraunhofer’s Ruben Meuth, the main objective of the project was to advance the production side of the process.

“The overall focus is on the reduction of manufacturing costs by significantly increasing production speed,” explained Meuth. “This innovative project is an excellent example of the collaboration between industry and research, and it shows how AM can be implemented into series production for luxury and sports cars.”

Alongside the “world’s first” 3D printed wheel carrier, the engineers participated in further joint workshops, which saw them redevelop several additional lightweight components. Within their research, the team also covered materials, processing, and quality assurance, and they’re currently examining other areas where applying additive technologies could be beneficial too.

“The component demonstrates the potential of additive manufacturing for future cars, and on top of that it’s a real eye-catcher,” concluded Carcioffi. “The project has shown that through additive manufacturing, we can entirely rethink many areas of the automobile, and lay the foundations for future innovations.”

Gaining performance from additive innovation

3D printing has been utilized by car manufacturers in a variety of ways in recent years, from BMW’s IDAM automation project to one-off additive components.

Sports Car manufacturer Porsche, for instance, has worked with TRUMPF and MAHLE to 3D print engine pistons for its 911 supercar. Integrating a cooling duct into the part’s ‘crown’ made it 10 percent lighter, and provided the car with an additional 30 BHP.

Elsewhere, additive manufacturing consultancy and Scalmalloy producer APWORKS has 3D printed a titanium exhaust tailpipe for the latest Bugatti Chiron. By fabricating the exhaust tailpipe with very thin walls, the engineers were able to cut weight by 50kg and increase the car’s overall downforce.

Automotive start-up Czinger has gone one step further and is even using 3D printing to produce load-bearing structural components for its upcoming 21C hypercar. Working with SLM Solutions, Czinger is developing a machine that’s specifically designed to print suitable parts for a performance vehicle.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the IAPT and FCA’s 3D printed wheel carrier. Image via the IAPT.