In the high-octane world of Formula 1, split seconds can mean the difference between success and failure, thus its teams push the sport’s technological boundaries to the absolute limit in pursuit of wins and championships.

Yet, while it has long been assumed that 3D printing is vital to the car iteration that ensues, the competitive nature of F1 means that many of its actual applications continue to be shrouded in mystery. One team that has begun to break that mold is the BWT Alpine F1 Team, which revealed in June 2021 that it uses 3D Systems’ Accura Composite PIV to create aero-part models for wind tunnel testing.

At the time, the disclosure provided a unique insight into the technology’s motorsport potential, but now taking the team’s open approach a step further, its Advanced Digital Manufacturing Manager Pat Warner has told 3D Printing Industry that it actually deploys 3D printing more extensively than many realize.

“Probably 70% of the bodywork you can see on a Formula 1 car in a wind tunnel is SLA 3D printed,” reveals Warner. “We can’t print things like front wing main planes or rear wing flaps, but pretty much everything else is open. If it’s not strong enough in SLA, we can do a secondary process of metal coating, which makes it a lot stronger. So most of our iteration testing is carried out with SLA.”

“We also use Selective Laser Sintering (SLS) to back that up,” he added. “We have a 3D Systems Figure 4 machine, which makes mold tools and the rubber gaiters for suspension shrouds. So the additive side of it, makes most of what goes into the wind tunnel.”

From Benetton to BWT Alpine F1

True to his word that BTW Alpine F1 “prides itself on being open,” Warner is kind enough to start our interview at the very beginning of the team’s adoption of 3D printing. Way back in 1998, the team was under different ownership, and would be known as Benetton for another three years. Having bought an SLA machine out of curiosity, Benetton then charged a young Warner with finding F1 applications for it.

Looking back, Warner reminisces about how the Mercedes AMG Petronas F1 Team’s CTO James Allison, who was then an aerodynamicist at Benetton, said that “SLA had no place in the wind tunnel.” Since then, the Advanced Digital Manufacturing Manager says his team (like many others on the grid) has built out its 3D printing capabilities considerably, “using it heavily” to create 450-600 parts per week.

“The main benefit [of 3D printing] is the ability to do more than one part at a time,” explains Warner. “On an SLA machine, you can print as many as you can fit on the bed. You can make any wacky shapes you like, which suits the aerodynamicists perfectly. It also detracts from the ‘production queue’ of the machines used to make a race car, especially in winter when we’re making all-new body panels/chassis.”

One area that 3D printing has proven particularly useful in, is Particle Image Velocimetry (PIV) data collection, a process in which a laser is used to assess the flow of particles over a given object. Leveraging 3D Systems’ Accura Composite PIV material, Warner says his team is now able to overcome the issue of background and particle reflections, challenges that can affect the quality of resulting data.

“The deep expertise of their application engineers and their industry-leading solutions have been an invaluable part of our innovation team,” Warner said when the project was unveiled. “It’s been exciting to co-develop Accura Composite PIV and see the benefits it’s bringing to our process. Due to the material’s unique optical characteristics, we are now collecting more reliable data from our PIV system in the wind tunnel.”

Addressing end-use F1 applications

In its current iteration, racing under the Renault-owned Alpine brand, the BWT Alpine F1 Team now utilizes 3D printing in all sorts of end-use applications as well. According to Warner, the blowers used to cool the team’s cars down when stationary are additively manufactured, as are the adapters used to plug them in, and the frames of the wheel nut guns deployed during mid-race pit stops.

On the subject of metal 3D printing, however, Warner is less optimistic that the technology is ready to produce end-use F1 components. Alluding to some recent tests carried out by his opposite numbers at the Aston Martin Aramco Cognizant and McLaren Racing teams, the Advanced Digital Manufacturing Manager even goes so far as to suggest that a lack of training can put users in danger.

“McLaren did a good job of nearly blowing someone up,” alleges Warner. “They were an early adopter of SLS, and they got rid of it rather quickly when they nearly took down their facility. They’re not the only people to do that, Aston Martin have done the same thing.”

“There was allegedly a small fire at Aston Martin a few months ago,” he added. “Well, it wasn’t a small fire, it was a large explosion that took out part of an exterior wall. So I’m telling you, you’ve got to think about it and make sure you’re doing it properly.”

Warner also cites the length of time needed to qualify materials and processes as a barrier to the technology’s adoption in F1, and with the sport having just agreed to a budget cap, he says teams are wary of investing in “white elephants.” What made these hurdles easier to overcome in aero-testing, Warner says, is the end-to-end nature of 3D Systems’ offering, and the expertise of its application engineers.

“I’m quite a big fan of a ‘one stop shop,’” concludes Warner. “It’s what I like about 3D Systems, we use their machines, service technicians, spare parts and software. The software was written to work on their systems using their materials, so if needed, then the engineers can come and see what went wrong. We’re trying to put all these jigsaw puzzles together to really get the right result.”

Where else is 3D printing used in F1?

Although the full extent of 3D printing adoption in F1 remains something of a mystery, we do know of a few more partnerships that have seen the technology deployed on-track. Williams Racing, for instance, worked with Nexa3D last season to produce functional Formula 1 wind tunnel parts leveraging the company’s high-speed NXE400 3D printer.

McLaren Racing is also understood to have used 3D printing trackside for tooling and prototyping since at least 2017. The team has a long-running partnership with Stratasys, which has seen it fabricate various different mock-ups and on-demand spare parts over the years, including brake cooling ducts, rear wing flaps and more.

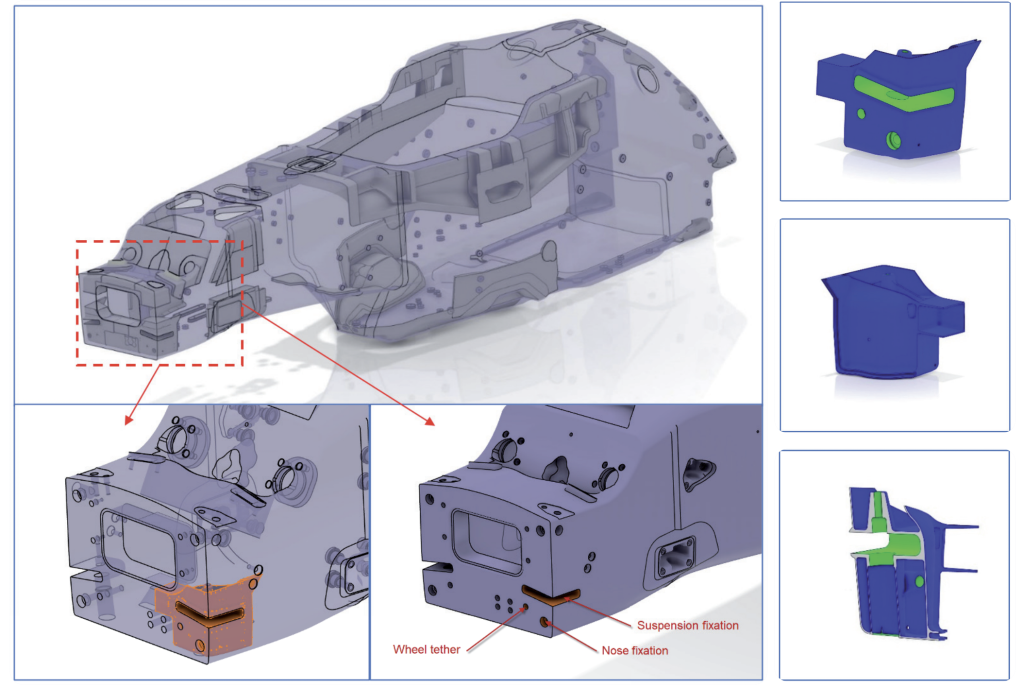

Despite Warner’s concerns over metal 3D printing, Alfa Romeo F1 Team ORLEN continues to collaborate with Additive Industries to 3D print critical components for its F1 car. While this year’s challenger features fewer additive manufactured aerodynamic parts than the last, more are now said to be structural, such as the suspension chassis inserts used to hold together its ‘C41’ race car.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows one of the BWT Alpine F1 Team’s cars in the pits at the Miami Formula 1 GP. Photo via the BWT Alpine F1 Team.