|

Listen to this article |

Reading Time: 3 minutes

Bollinger Motors supplies Class 3-6 electric platforms for commercial trucks. The company was founded by industrial designer Robert Bollinger in 2015, who designed the Class 3 electric pickup trucks the B1 and B2. Bollinger talks to Auto Futures about the unique features of the chassis, battery management and changeable upfitting.

“Back when we built the B1 and B2, we displayed the chassis by itself. That is when a ton of fleets and upfitters came to us and asked, ‘Can you make this for commercial applications?’” says Bollinger.

Michigan-based Bollinger Motors started a parallel path of making commercial chassis. It was similar and less complicated than the off-road trucks, says Bollinger.

“Those years of work have been mostly concentrated on controls and software integration of all the components such as thermal management. All the work to make sure that the truck is always running. It never breaks down. So, it’s not one particular technology you get but it is a whole entire thing,” he says.

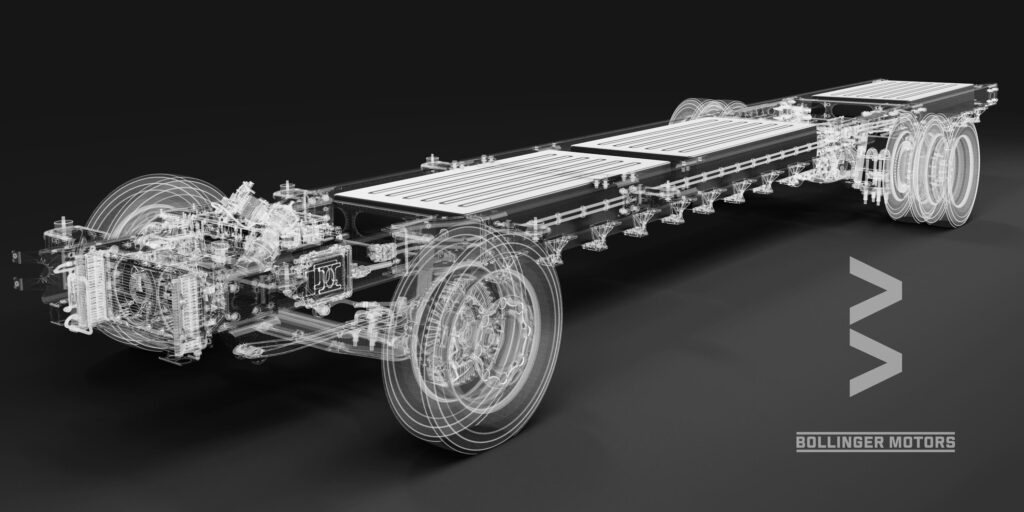

The first thing people notice about the Bollinger chassis is the clean design.

The design is clean. Bollinger widened the frames a bit wider than most trucks have their frame rails. The rails are widened to keep the batteries totally inside. While some of the other trucks have the batteries sticking out, says Bollinger.

Commercial fleet owners also like double wheels in the back.

“What is really important for fleets is that you have a solid rear axle because that is what carries all the weight. We believe it is a better solution than ones that have motors in the wheels. Commercial fleets need dual wheels in the back and solid rear axles. We can cover a lot of classes. We can do three, four or five axles,” says Bollinger.

“What differentiates us is that many companies that people say are our competition are doing one particular kind of vehicle. A lot of them are doing walk-in vans only. What we are doing is offering Class 3 through Class 6. And we are offering both a platform and chassis cab. We can do walk-in vans, box trucks, flat trucks or state trucks. So basically, any kind of vehicle you need, or any fleet needs – we can provide them,” he explains.

“All the years of thermal were an insane amount of work.”

The company is working with upfitters to provide the rest or convert anything needed, says Bollinger.

“We are working with Roush to assemble platforms and chassis cabs. We are working with existing upfitters. We are working with all of them to provide what is right for the client.”

Bollinger Motors has been in the Class 3 all-electric space for seven years. Where the company has the most experience in Class 3 and electricity. Therefore, the first vehicle they will launch will be a Class 3, says Bollinger.

Bollinger Motors learned from developing the Class 3 truck about supply relations and thermal controls. The company filed a patent for its thermal controls. It also offers a BMS (battery management system) for its platforms.

“All the years of thermal were an insane amount of work. It takes years to get to the point where you are where you have it right so that our thermal is great. Our supply base is great. We have long relationships with the people who can make the equipment we need. Anyone coming into the game now, starting those relationships, it is going to be hard. Because everyone’s at full capacity.”

The Bollinger B2 was shown at the Con Edison exhibit at the New York Auto Show this spring. Then Con Edison asked Bollinger Motors to develop a Class-3 prototype of a walk-in van for testing.

Auto Futures asked: ‘What will the vehicles cost and what will be next for Bollinger Motors?’

“Most companies have not announced pricing yet. By de-risking and working with all the Tier-Ones, we are trying to bring down costs,” says Bollinger, “We will have another announcement about a sales and service partner. We will be putting ourselves into the ecosystem that already exists.”