Mahle headquarters StuttgartMahle CEO Jörg Stratmann is now taking firm action in his austerity program: the fourth-largest German automotive supplier plans to phase out the facility in Öhringen by the end of 2020. So far, 240 employees have been manufacturing air management systems for internal combustion engines there. The plant has been under price pressure… Continue reading Savings program: Auto supplier Mahle closes plant in Öhringen

Tag: Tier 1 Suppliers

06/25/2019MAHLE plans closure of its location in Öhringen

MAHLE plans closure of its location in Öhringen

Stuttgart/Germany, June 25, 2019 – MAHLE is planning the closure of its Öhringen location in Germany. All on-site operations will be closed in stages up to the end of 2020. The location currently has 240 employees manufacturing air management systems for combustion engines.

Home

Press

Press releases

Press release [PDF; 33 KB] High price pressure: location no longer competitiveNo new orders despite comprehensive countermeasuresClosure in stages up to the end of 2020 On account of its product portfolio, the location has already been under increasing price pressure for several years, particularly due to competition from best-cost locations. Plant structures have been continuously adapted for the deteriorating environment with numerous cutbacks at the location. “Unfortunately, we have now reached a point where the outlook for the plant is not sustainable,” states Wilhelm Emperhoff, Member of the Management Board of MAHLE responsible for the Filtration and Engine Peripherals business unit as well as the Mechatronics division.

The location’s cost structures do not allow for the acquisition of new projects, and most recently, even follow-up orders for existing products with low investment expenditure could no longer be placed in the market. MAHLE’s efforts to generate a sustainable outlook for the Öhringen location with new products and technologies have also proven unsuccessful. We were unable to win any new projects.

As a result of the high financial cost of transformation in the automotive industry, ongoing economic slowdown, and declining demand for diesel vehicles, MAHLE operates in a challenging competitive environment and is increasingly reliant on profitable and sustainable locations. “This is a tough decision for us, but it is unavoidable given the prevailing situation and negative prospects for the Öhringen location,” states Emperhoff.

In the coming weeks, MAHLE will begin discussions with employee representatives with the aim of making the closure of the location as socially responsible as possible.

About MAHLEMAHLE is a leading international development partner and supplier to the automotive industry as well as a pioneer for the mobility of the future. The MAHLE Group is committed to making transportation more efficient, more environmentally friendly, and more comfortable by continuously optimizing the combustion engine, driving forward the use of alternative fuels, and laying the foundation for the worldwide introduction of e-mobility. The group’s product portfolio addresses all the crucial issues relating to the powertrain and air conditioning technology—both for drives with combustion engines and for e-mobility. MAHLE products are fitted in at least every second vehicle worldwide. Components and systems from MAHLE are also used off the road—in stationary applications, for mobile machinery, rail transport, as well as marine applications.

In 2018, the group generated sales of approximately EUR 12.6 billion with more than 79,000 employees and is represented in more than 30 countries with 160 production locations. At 16 major research and development centers in Germany, Great Britain, Luxembourg, Spain, Slovenia, the USA, Brazil, Japan, China, and India, more than 6,100 development engineers and technicians are working on innovative solutions for the mobility of the future.

For further information, contact:MAHLE GmbH

Ruben Danisch

Corporate Communications/Public Relations

Pragstraße 26–4670376 Stuttgart/Germany

Phone: +49 711 501-12199

ruben.danisch@mahle.com

Autonomous driving at the BMW Group: #NEXTGen 19.

Technologies for an on-demand mobility scenario.How about taking the BMW 7 Series out for a spin – and watching a film or even closing your eyes for a while? The BMW Group makes all this possible – and is providing a glimpse of autonomous driving at #NEXTGen. In an urban on-demand mobility scenario, a BMW… Continue reading Autonomous driving at the BMW Group: #NEXTGen 19.

Right-Turn Assist System for Passenger Cars Protects Cyclists and Pedestrians

New short-range radar allows for more precise detection of vehicle surroundings Technology forms basis for a Right-Turn Assist Compact radar system operates within high-resolution 77 Gigahertz range Frankfurt, Germany, June 25, 2019. Technology company Continental has unveiled a new short-range radar which represents the next development stage towards even more precise detection of the vehicle… Continue reading Right-Turn Assist System for Passenger Cars Protects Cyclists and Pedestrians

Russia’s Yandex plans bold step for self-driving cars – Automotive News

Tweaks remaining before driverless operations, Polishchuk says, aren’t safety-related. There’s one specific spot where vehicles need to make a U-turn, and engineers are considering how to make the turn without confusing human drivers in the vicinity. In another area, near a bus stop, there’s a crosswalk in which pedestrians congregate. As they mill about, sometimes… Continue reading Russia’s Yandex plans bold step for self-driving cars – Automotive News

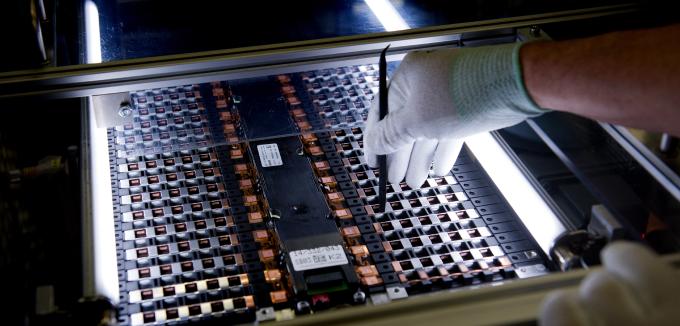

Peter Altmaier’s electromobility plans: With three battery consortia to the electric car world champion

DPA Battery of a smart electric car: Three consortiums will in future produce lithium-ion cells in Germany Federal Minister of Economics Peter Altmaier has last for his industrial strategy a lot of criticism plug in have to. With a central project in the course of this strategy the CDU man obviously advances: So Altmaier wants… Continue reading Peter Altmaier’s electromobility plans: With three battery consortia to the electric car world champion

Electric Jaguar XJ flagship to compete with Tesla Model S

Jaguar Land Rover plans to launch its new flagship with a jolt. At a recent investor day, the company said its new flagship XJ sedan will launch first as an electric model, likely in 2020. Models with gas engines are expected to follow.

The automaker previously announced it will offer electric and plug-in hybrid versions of every model it sells by 2025. The new XJ is expected to be the first of those models based on a new modular architecture designed to accept both electric and gas platforms.

The electric XJ will likely have a 90.2 kilowatt-hour battery with a targeted range of 292 miles, according to Nick Miles, JLR's head of product engineering, as presented at the investor day. That range is likely on the somewhat optimistic new European WLTP driving cycle.

The new “Modular Longitudinal Architecture” is unrelated to the platform underpinning Jaguar's electric I-Pace, which is built at a Magna-Steyr contract manufacturing facility in Austria. The XJ and vehicles on its modular MLA platform will be built at Jaguar's home factory in Solihull, England.

2020 Land Rover Range Rover

The new platform will also underpin two new SUVs from Range Rover, a new flagship Range Rover in 2021 and a new Range Rover Sport a year later, according to a report in Automotive News Europe (subscription required.) Both Range Rovers will be offered with plug-in hybrid powertrains, and at least one of Range Rover's four models will include a fully electric option.

Both the Range Rover and the Range Rover Sport currently include plug-in hybrid options, but they're based on an older platform, one not shared with Jaguar. The new plug-in hybrid models are expected to achieve a slightly longer electric range.

The MLA platform is expected to replace five platforms the company currently uses, but may not be the company's only electric architecture. Outgoing design head Ian Callum told Automotive News that the I-Pace platform is also likely to continue to underpin new, updated electric models.

Here’s How Magna Steyr Builds the 2019 Mercedes-AMG G 63 In Austria

autoevolution

cars

moto

news

car reviews

spyshots

driven cars

space junk

green

newspaper

Compare Cars

BAC Calculator

Editorial

Coverstory

Motorsport

Testdrives archive

Auto Shows

Tuning

Car Finder

Photo of the Day

Glossary of automotive terms

Masthead

RSS Feeds

More on this:1 Suzuki Jimny Gets Mercedes-AMG G63 Conversion in China, Bull Bar Included2 Mercedes-AMG G63 Two-Door Looks like a Suzuki Jimny on Steroids3 Topcar Reveals Mercedes GLE Coupe-based Inferno 4×4*24 Mercedes-Benz G63 AMG Gets 2JZ Engine Swap in Dubai, Sounds Like an AK-475 New Mercedes-AMG CLA45 Shooting Brake Rendered, Looks Spot On

Space Junk

This Is How the Wheels NASA's New Rover Will Use Look Like

Here’s How Magna Steyr Builds the 2019 Mercedes-AMG G 63 In Austria

15 Jun 2019, 12:42 UTC ·

by Mircea Panait

Home > News > Car Profile

Building a sport utility vehicle doesn’t come cheap, especially a body-on-frame legend in the off-road such as the Geländewagen. The high-quality parts, bundles of technological wizardry, and labor costs in Austria are a few of the culprits, but nevertheless, the G-Class is worth your hard-earned cash.

54 photos

The cheapest specification starts at $124,500 in the United States, but Europeans are treated to the more affordable G 350 d at €95,021.50 in Germany. At the opposite end of the spectrum, the G 63 takes the crown in every single aspect. But have you ever wondered how the G-Class is manufactured?

Since the beginning, the Geländewagen was manufactured in Graz by Magna Steyr with close attention to detail. In other words, the production output doesn’t match that of regular SUVs. In July 2017, the 300,000th example of the breed rolled off the assembly line, and the numbers keep increasing since the arrival of the new G.

Shmee150 (a.k.a. Tim Burton) bought one of these gentle giants, and thanks to his status in the automotive world and YouTube creators community, the three-pointed star invited him to check out how the W463 is manufactured. “Wait, wasn’t W463 used for the previous generation?” You’re right, dearest reader, but the higher-ups decided to keep the codename instead of switching to W464.

The production process starts with the bodies of the G-Class arriving at Magna Steyr, then the specialized personnel builds the vehicle, one part and subassembly at time. Among others, Shmee150 was allowed to fit the steering wheel and airbag to the G 63 of his dreams.

In regard to suck-squeeze-bang-blow, the metallic black SUV features a 4.0-liter V8 with twin turbocharging that originates from Affalterbach. Codenamed M177, this engine differs from the Mercedes-AMG GT series through the wet-sump lubrication system and AMG Speedshift TCT 9G automatic transmission.

Tuned to 585 PS (577 horsepower) and 850 Nm (627 pound-feet) of torque, the M177 is more potent than the M157 in the previous generation of the G 63. On that note, the G 65 has been discontinued because Mercedes-AMG is focused on V8s and electrification.

The M279 engine, a 6.0-liter V12 with twin turbocharging, will be discontinued at the end of the production cycle of the S 65. Tobias Moers, the head honcho of Mercedes-AMG, also confirmed the S 65 will be discontinued with the arrival of the W223 generation S-Class.

click to load Disqus comments for this storyThis enables Disqus, Inc. to process some of your data.

The Perversion of the Fast and the Furious

Upgrading Your Car: Top 5 Android Auto / Apple CarPlay Multimedia Systems

Headwave TAG Helmet Music and Navigation System Reviewed

Manipulated Into Liking Cars

Engine Break-In: What You Need to Know

Can Cars Be Hacked? Inside Secure CSO Asaf Ashkenazi Says Yes. By Anyone

The Engine Start-Stop Systems Conspiracy

5 Top Rated Electric Scooters to Cure Your Lime and Bird Addiction

Alfred Neubauer: the First “Don” of Motor Racing

Smoke and Mirrors: Volvo's New Top Speed Limit

5 Must Have Truck Bed Accessories Your Pickup Badly Needs

Interview with Lamborghini EMEA CEO, Andrea Baldi: Hybridization, Female Buyers

Car, Go Make Me Some Money!

Get Your Kids Driving This Summer: 5 Best American Ride-On Toys

The Biggest Anticipations in Motorcycling for 2016, Part 1

On Electric Harleys and New Generations

The Dos and Don’ts of Washing a Motorcycle, Part Two (Final)

When Ford Told Ferrari to Shove It Using a Race Car

Could Volkswagen Group's Electric Plans Include Ducati?

The Dos and Don’ts of Washing a Motorcycle, Part One

Aprils Fools' Pranks We’d Love or Hate to See Come True

Mercedes-AMG models:Mercedes-AMG CLA 35 4MATIC Shooting Brake CompactMercedes-AMG GLC 63 4MATIC Coupe Medium SUVMercedes-AMG GLC 63 4MATIC Medium SUVMercedes-AMG CLA 35 CompactMercedes-AMG A 35 4MATIC Sedan Entry PremiumAll Mercedes-AMG models

googletag.cmd.push(function(){ window.slot4 = googletag.defineSlot(“/1004334/AE_news_300x600_noref”, [300, 600], “AE_news_300x600_noref__slot_4”).addService(googletag.pubads()); googletag.display(“AE_news_300x600_noref__slot_4”); });if(typeof window.REQUEST_NONPERS !== “undefined”) { console.log(“manref”); googletag.pubads().refresh([window.slot4]); } '+'ipt>';

if(i==3) txt+='googletag.cmd.push(function(){ window.slot5 = googletag.defineSlot(“/1004334/AE_news_300x250_noref”, [300, 250], “AE_news_300x250_noref__slot_5”).addService(googletag.pubads()); googletag.display(“AE_news_300x250_noref__slot_5”); });if(typeof window.REQUEST_NONPERS !== “undefined”) { console.log(“manref”); googletag.pubads().refresh([window.slot5]); } '+'ipt>';

}

txt+=””+

“”+

“”+data[i][0]+””+

“”+

“”+

“”+data[i][2]+”

“+

“”+

“”+

“”;

}

txt+=””;

$('#morescroll').html(txt);

nxloaderactive=false;

});

}

function aenext_lzy() {

$(window).on(“scroll”, function() {

if(nxstories!=false) return;

var footOffset = $(“#footer”).offset().top;

if($(window).scrollTop() > footOffset – $(window).height() – 600) aenext_load();

});

}

function aenews_fixoverlaps_actual() {

window.aeoverlapst=-1;

var $rsoc=$(“.rightsocial”).first();

if($rsoc.length!=0) {

var rsocofs=$rsoc.offset().top;

var $newsgal=$(“.newsgal”).first();

if($newsgal.length==0) return;

var ngofs=$newsgal.offset().top+$newsgal.height();

if(rsocofs commentsOffset – $(window).height() – 400) anyclip_load();

}

}

}

function anyclip_load() {

var d = document, s = d.createElement('script');

s.src = 'https://player.anyclip.com/anyclip-widget/lre-widget/prod/v1/src/lre.js';

s.setAttribute('id', 'lre-player-widget');

s.setAttribute('pubname', 'autoevolutioncom');

s.setAttribute('widgetname', '0011r00002IZQzB_730');

(d.head || d.body).appendChild(s);

window.acLoaded = true;

}

Continental calls on its employees across Europe to vote in the European Parliament election 2019

Continental calls on its employees across Europe to vote in the European Parliament election 2019

HANOVER, 14-May-2019 — /EuropaWire/ — Continental calls on its employees across Europe to vote in the European election, which will take place between May 23 and 26, 2019. The European Parliament election 2019 is going to be the 9th parliamentary election since the first direct elections held in 1979.

Dr. Elmar Degenhart, Chairman of the Executive Board Continental AG

Commenting on the European Parliament election 2019, Continental CEO Dr. Elmar Degenhart, said:

“For decades, the European Union has been the most successful foundation yet for freedom and peace in Europe and our prosperity. In global competition, we can only win together as self-assured Europeans. Anybody who does not vote is allowing others to determine their fate. Europe’s voice counts most when we all amplify it with our own.”

Dr. Ariane Reinhart who is Executive Board member for Human Relations at Continental , commented further:

Dr. Ariane Reinhart, Member of the Executive Board, Human Relations, Director of Labor Relations, Sustainability

“Two thirds of German exports go to European countries. This means customers in Europe ensure that we have work here. A strong EU that is developing well secures the future of our jobs.”

The European Single Market is Continental’s strongest market in terms of sales. Continental’s turnover in Europe is €21.8 billion in 2018, which represents 49 percent of the company’s global sales of €44.4 billion for that year. In terms of employees, more than 50% (57 percent or roughly 140,000 staff ) of its global workforce (around 245,000 staff) are based in more than 250 European locations in almost all EU countries. The majority of its 49,000 engineers around the world work in Europe.

More than €12 billion has been invested in safe, clean, intelligent mobility across Europe by Continental over the past 10 years.

Dr. Ariane Reinhart warns against taking freedom and democracy for granted. He added:

“Freedom and democracy are the insurance cover for our community. We must defend both foundations and continually renew them. Voting in the European election is therefore an important commitment to democracy and economic growth. The long, drawn-out disputes surrounding the uncertain Brexit show us what “less EU” leads to: border fences, dislocations, fewer opportunities, and uncertain prospects.”

In particular, Dr. Reinhart called on eligible voters with higher aspirations to determine their own future. “There is a lot on the line here for them, because setbacks in the process of European unification reduce their opportunities for growth, just as they do for all of us. In times of international trade disputes and when tariffs have returned, a weakened Europe is a plaything for other, less liberal powers. A strong, European community and a strong European Single Market are the best way to protect our social, economic, and ecological climate.”

A strong Europe has a political and cultural significance for Continental, in addition to its economic relevance. European and internationally active companies bear responsibility for highlighting the benefits of a united, values-based Europe for their employees, according to Dr. Ariane Reinhart.

She added further: “Europe is a community of shared values, just like Continental. The corporate values For One Another, Freedom To Act, Trust, and Passion To Win that we embrace reflect the values of the European idea and support them. We understand it to mean that employees stick together, join forces, and work for one another as well as see and use the diversity in our company as a source of inspiration and creativity.”

The European idea has been promoted by Continental for two years now. It is giving young people the chance to experience the opportunities that a united Europe offers in the labor market, in particular. Continental has initiated the “Experiencing Europe” program in 2017, which offers a chance to young adults in Germany, who are seeking work, to complete two internships, each lasting two weeks, in another European country. On the other side, young people from other countries can complete an internship in Germany. In addition to Continental, the internship scheme includes companies like Schaeffler, Thomas Cook, and DHL. Thus far, some 100 young people have taken part in the program. The apprentices can use this international experience to improve their profile and secure a job at one of the companies involved. Four participants are currently completing an apprenticeship at Continental, and one is completing a work-study program at the company.

Media contacts:

Nicole Göttlicher

Spokeswoman, HR

Corporate Communications

Phone: +49 511 938-1640

E-mail:

nicole.goettlicher@conti.de

Vincent Charles

Head of Media Relations

Phone: +49 511 938-1364

E-mail:

vincent.charles@conti.de

SOURCE: Continental

MORE ON CONTINENTAL, EUROPEAN PARLIAMENT, EUROPEAN UNION, ETC.:

European Commission: more efforts needed from the European Parliament and the Council to deliver results on all pending security proposals ahead of the EP elections in May 2019Intelligent digital tachographs: Tips and information on how to make a smooth transition to the DTCO 4.0EU unveils an Action Plan to step up efforts to counter disinformation in Europe and beyondWind energy continues to grow as share in EU’s electricity mixEPP Group: European Commission and Member States need to ensure sufficient funding to streamline digital technologies into all aspects of development policyEuropean Parliament to host “The future of international election observation” conference, 10-11 OctoberTowards a Europe of Stakeholder NationsEU on track to launch its most ambitious ever European research and innovation programme in 2021European Parliament and the Council reach political agreement on combating fraud and counterfeiting of non-cash means of paymentContinental's 4Q bolstered in part by strong sales of winter tires and the positive market development in the non-automotive industrial businessContinental’s powertrain business now Vitesco Technologies; partial IPO planned for the 2H 2019Strengthened Schengen Information System: New alerts on criminals; Greater vigilance; Stronger data protection; Improved interoperability

EDITOR'S PICK:

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 10 and 14 June 2019

Digi Communications N.V.: Reporting of legal documents concluded by the company in May 2019 in accordance with article 82 of Law no. 24/2017 and FSA Regulation no. 5/2018 published

DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions occurred under DIGI symbol between 3 – 7 June 2019

PDA Explores the Transformation of Healthcare at 4th Annual European Meeting

ASI President John Cross Named AGMA Chairman

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 27 – 31 May 2019

Breakthrough on laser powder bed fusion technology brings effective production of larger componentscloser to mainstream

PDA Announces All-Star Speaker Lineup for Advanced Therapy Medicinal Products Conference

Digi Communications N.V.: Exercise of stock options by the Executive Directors of the Company

Digi Communications N.V. announces DIGI Kft., the Hungarian subsidiary of the Company, launches mobile telephony services in Hungary

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 21 and 24 May 2019

ZYXEL READY WITH 5G SAMPLES IN AUGUST 2019

Digi Communications N.V. announces the initiation of the share buy-back program as authorized by the Company’s GSM on 30 April 2019

Digi Communications N.V Q1 2019 Financial Report and the report regarding legal documents for April 2019, in accordance with article 82 of Law no. 24/2017 and FSA Regulation no. 5/2018 released

Digi Communications N.V. announces the new date of the Conference Call for the presentation of the Q1 2019 Financial Report. Update to the Company’s 2019 Financial Calendar.

Rhenium-SCT® (SCT= Skin Cancer Therapy) now being offered in Hanau, Germany

Project consortium aims at driving the adoption of selective laser melting (SLM) for large scale metal parts printing

Digi Communications N.V. announces the availability of the instructions on the 2018 share dividend payment

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 29 April 2019 – 1 May 2019, under the class B shares buy-back progr

Biodiversity Report Is Urgent Call to Action Beyond Fixes; Geneva Global Initiative Calls on World Community to Focus on Concrete Actions

Digi Communications N.V.’s general Shareholders’ meeting resolutions from 30 Apr 2019 approving, amongst others, the 2018 Annual Accounts and the availability of the adopted Annual Financial Report for the year ended Dec 31, 2018

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions occurred under DIGI symbol, 22 – 26 April 2019

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 15 April 2019 – 19 April 2019s

XPAND Code was successfully scanned from 200 meters/700 feet at Olympics stadium

Wasser eingießen, Warten und Einschalten

Digi Communications N.V.: Reporting of legal documents concluded by the company in March 2019 in accordance with article 82 of Law no. 24/2017 and FSA Regulation no. 5/2018 published

Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 8 and 12 April 20..

AEye Team Profile: Vivek Thotla

On June 26th, AEye Staff Engineer, Vivek Thotla, will be speaking on a panel called “Should We Take CV To The Edge?” at IoT Forum on Computer Vision @ Sensors Expo.

Vivek is a staff engineer at AEye, where he leads product verification and validation, and is responsible for LiDAR simulation and data strategy in producing automotive grade products. Previously, he was a Component Owner / Functional Delivery Owner for point cloud algorithms at Continental, where he was responsible for planning, requirements, design and development of embedded platform-based algorithms for a Hi-Res 3D Flash LiDAR, in addition to enforcing ADAS process stages to meet ASPICE levels and functional safety. He has also held engineering roles at Tribis, AmpliSine Labs, Missouri S&T and Enigma Portal. Vivek holds an MBA in Information Technology Project Management and a PhD and Masters in Electrical, Electronics and Communications Engineering.

We sat down with Vivek to learn more about the advantages of integrating computer vision at the sensor, building automotive grade LiDAR products, and why he decided to move to the Bay Area.

Q: How much of an autonomous vehicle’s computer vision should be done at the sensor, as opposed to a central processor?

The amount of data produced today by a perception system is enormous. And incorporating all the data from the different kinds of sensors used (like radar, camera, and LiDAR) makes it very difficult and expensive to process and store. In a typical perception system, roughly 80% of the data produced by the sensors is thrown out.

However, intelligent sensors – like what we develop at AEye – are software definable. Meaning, you can adjust its settings to get high resolution data from an object and get sparse data in the background, cutting down the overall amount of data processed by more than 80%. This makes computer vision algorithms at the central processor faster and efficient because once you preprocess data, latency becomes less of an issue. Currently, AV companies are spending a tremendous amount of money storing useless data. Preprocessing saves both time and money.

Q: What is the largest challenge in producing automotive grade LiDAR products?

Industry wide, the greatest challenge is maintaining the quality, reliability, and consistency needed on all components and software that go into a LiDAR sensor of over 100,000 samples or more and over the sensor’s lifetime. Another major challenge for bringing LiDAR products to the automotive market is designing the sensor to fit in different regions of the car. There are a lot of constraints based on where the sensor is placed on the vehicle and certain issues that arise from each placement. For example, a sensor placed behind a windshield might need a completely different design than a sensor that’s placed in the front bumper.

There are many interesting LiDAR architectures out there that work really well at smaller samples and in the lab. But the moment the product needs to scale and deal with all the quality and environmental requirements of being an automotive grade product, they fail. AEye is mitigating these challenges by partnering directly with Tier 1’s who know the process of making large-scale, automotive grade products. In my own experience, I’ve found that once a Tier 1 partners with you, they are extremely supportive because they believe in you, and that proves you are capable of achieving it.

In addition to our partners who help us push the sensor to automotive grade, we have a great functional safety team here at AEye. I came to AEye from a Tier 1, so I know what goes into developing an automotive grade sensor, and the AEye team is made up of people from all over the automotive industry that have great, diverse insight into how to bring a product to market.

Q: You moved to the Bay Area from Santa Barbara. What was it about Silicon Valley that drew you here?

It has always been my dream to come to Silicon Valley – you hear about it so much as the epicenter of technology and innovation. And it’s true: Silicon Valley is at the heart of the autonomous driving industry. All the innovative and novel work happening today in the LiDAR industry is happening here and I did not want to miss my chance to help develop the tools for true autonomy.

Connect with AEye at Sensors Expo! Learn more here.

AEye Team Profile: Vivek Thotla — VentureBeat Says iDAR Is “Built for Speed”AEye Team Profile: Dr. Allan SteinhardtAEye Adds VP of AI and Software to Executive TeamAEye Advisory Board Profile: Scott PfotenhauerThe Future of Autonomous Vehicles: Part II – Blind Technology without Compassion Is RuthlessAEye Advisory Board Profile: Adrian KaehlerAEye Team Profile: Indu VijayanAEye Expands Business Development and Customer Success Team to Support Growing Network of Global Partners and CustomersAEye Sets New Benchmark for LiDAR Range