The electric version of the next-generation Peugeot 208, due next year, will not get its own bespoke look, the company’s design boss, Gilles Vidal, has told Autocar. Vidal said the new electric supermini will receive very few modifications, such as a flat front grille and some EV-specific submenus in its infotainment system. “We do not… Continue reading Electric Peugeot 208 won’t get bespoke design

Category: Automotive

VW Group hit hard by new emissions test

To gauge the impact of WLTP, an Autocar survey of car firms revealed that, while most were expecting no issues or delays due to WLTP, several have been forced to suspend production or axe models to meet the new rules. Volkswagen Group brands have been particularly affected by the change in tests. Audi, Seat, Skoda… Continue reading VW Group hit hard by new emissions test

Unterschleißheim applies for Autonomous E-Bus

The city of Unterschleißheim plans to introduce an autonomous electric bus in the city. The city Unterschleissheim in the north of Munich is especially known for the BMW location. Because BMW there bundles his ambitions regarding autonomous driving. Since it seems logical that the city wants to have to do with the technology. Autonomous E-Bus… Continue reading Unterschleißheim applies for Autonomous E-Bus

The Stunning One-Year Turnaround of GM’s German Castoff

Terms of Service Violation Your usage has been flagged as a violation of our terms of service. For inquiries related to this message please contact support. For sales inquiries, please visit http://www.bloomberg.com/professional/request-demo If you believe this to be in error, please confirm below that you are not a robot by clicking “I’m not a robot”… Continue reading The Stunning One-Year Turnaround of GM’s German Castoff

Fiat Chrysler's top ranks in limbo after Marchionne's death

Original Article

Kia Motors to launch vehicle in India next year

{{if trimcom}}{{:trimcom}}{{else}}{{:comment.substr(0,500)}}{{/if}} {{if comment.length > 500}} … Read More {{/if}} Startup delivers groceries in self-driving cars Toyota to invest Rs 3500 crore in Uber for self-driving cars Rare Ferrari 250 GTO sells for record Rs 334 crore at auction Go to Source

Hybridization in the commercial vehicle: scalable to every application

Press releases

Press archives

Media service

Publications

Press contact

Home

Press

Press releases

Hybridization in the commercial vehicle: scalable to every applicationStuttgart, August 28, 2018 – Particularly in the commercial vehicle sector, new regulations concerning the reduction of CO2 and emissions will be the technological driver in the ongoing development of the powertrain. Even more than in the passenger car segment, the broad spectrum of drive architectures and application areas will produce a rather heterogeneous environment. Hybridization in all its forms is therefore a highly promising avenue. MAHLE offers solutions to technological change, from thermal management to drive motors and power electronics.

Press release [PDF; 306 KB]Press picture [JPG; 8 MB] Hybridization of the commercial vehicle powertrain as a flexible approach to CO2 reductionBroad diversification: from the 48-volt mild hybrid to the high-voltage system—significant CO2 reductions are possibleSystems solutions from MAHLE for all hybrid architecturesThe question of whether and in what form electrification will make its entry into the commercial vehicle sector depends, even more than with passenger cars, on the additional costs and net benefit for the relevant application, with legal CO2 limits and fuel prices defining the framework. When it comes to commercial vehicles, the degree and nature of electrification will be heavily dependent on the actual application.

At the two extremes are purely electric fuel cell trucks and highly efficient vehicles driven by a combustion engine. Between the two is a whole spectrum of various forms of electrification or hybridization of the powertrain.

Hybrid technology offers considerable potential for CO2 savings, with maximum flexibility in terms of applications: electrification of auxiliary components, mild hybrid applications with 48-volt drive motors in parallel (recuperation/boosting), high-voltage or serial architectures, and plug-in hybrids (purely electric driving for long distances).

48-volt system: 10 percent less CO2 in distribution transportFor light- and medium-weight commercial vehicles up to 12 metric tons in distribution transport, MAHLE offers a robust, compact 48-volt drive system with water cooling and integrated electronics, providing a power output of up to 30 kW. Because of the low level of waste heat from the electric drives (boosting/recuperation) connected in parallel, the cooling architecture used for vehicles with a combustion engine or battery can be adapted easily and effectively for this price-sensitive application area.

Consistent use of electrically driven, beltless auxiliary components—such as electric fans, electric air conditioning compressors, or electric main coolant pumps—can produce a total CO2 savings potential of around 10 percent in urban distribution transport.

High-voltage full hybrid: 5 percent less CO2 with heavy-duty commercial vehiclesAt the other end of the hybrid spectrum, for heavy-duty commercial vehicles up to 40 metric tons, electrical drive outputs of approximately 50 to 100 kW are required, depending on the specific application. High-voltage systems in this segment can achieve a CO2 reduction of up to 5 percent. Thermal management plays a crucial role in making optimal use of the CO2 savings potential.

Demand-based soaking of the temperature-sensitive lithium-ion battery is essential. Air conditioning is therefore becoming part of the battery and electronics thermal management. The charge air cooling and air conditioning condenser can be recooled indirectly via a low-temperature coolant cooler. This makes the design of the (two-level) cooling module significantly easier. Thanks to the improved aerodynamics, this also has a positive impact on fuel consumption.

With the Visco® hybrid fan drive, MAHLE offers a solution tailored specifically to this application. The MAHLE technology combines the advantages of the Visco® drive with the advantages of electric actuation:

Fan performance controlled on demandElectric motor takes over in the event of reduced fan engagement, improving fan efficiencyPossibility of energy recuperation from the fanPossibility of purely electric operationGenerally improved control behavior thanks to the combination of Visco® and electric motorMAHLE is ready for all hybrid levelsThe hybrid drive will be used in all its forms due to the variety of weight classes and load profiles in the commercial vehicles segment—from the mild hybrid with a 48-volt drive to the powerful high-voltage system. One of the main drivers is CO2 legislation. With its comprehensive product portfolio, MAHLE covers all hybrid systems in the commercial vehicles segment and offers tailored solutions to achieve maximum CO2 savings.

About MAHLEMAHLE is a leading international development partner and supplier to the automotive industry as well as a pioneer for the mobility of the future. The MAHLE Group is committed to making transportation more efficient, more environmentally friendly, and more comfortable by continuously optimizing the combustion engine, driving forward the use of alternative fuels, and laying the foundation for the worldwide introduction of e-mobility. The group’s product portfolio addresses all the crucial issues relating to the powertrain and air conditioning technology—both for drives with combustion engines and for e-mobility. MAHLE products are fitted in at least every second vehicle worldwide. Components and systems from MAHLE are also used off the road—in stationary applications, for mobile machinery, rail transport, as well as marine applications.

In 2017, the group generated sales of approximately EUR 12.8 billion with about 78,000 employees and is represented in more than 30 countries with 170 production locations. At 16 major research and development centers in Germany, Great Britain, Luxembourg, Spain, Slovenia, the USA, Brazil, Japan, China, and India, around 6,100 development engineers and technicians are working on innovative solutions for the mobility of the future.

For further information, contact:MAHLE GmbH

Christopher Rimmele

Corporate Communications/Public Relations

Pragstraße 26–46

70376 Stuttgart/Germany

Phone: +49 711 501-12374

Fax: +49 711 501-13700

christopher.rimmele@mahle.com

Annual report

This was our year 2017

Download

[PDF; 5087 KB]

Key figures

[PDF; 1464 KB]

Annual report website

MAHLE Performance

Our customer magazine

More

Electromobility as an opportunity

“ Carmakers never bothered with the issue of fuel supply for combustion engines; they just left it up to the oil companies. Why has Porsche Engineering decided to develop its own charging park for electric cars? Michael Kiefer (M.K.)— With the transition from combustion engines to electric drive units, I have to bring my customers… Continue reading Electromobility as an opportunity

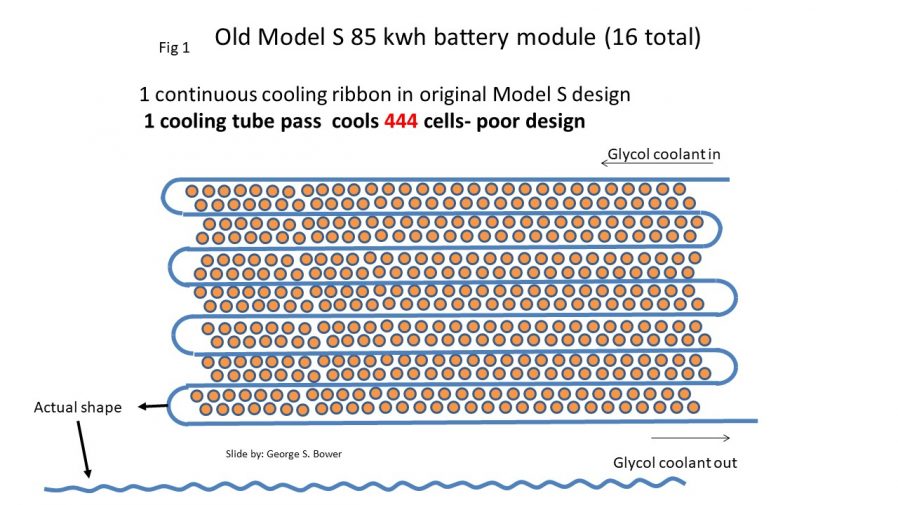

Tesla Model 3 Battery Can Transfer Twice The Heat Of Model S P100D

Track Data backs up our detailed Thermal Analysis In a previous article, we explained in words why the Tesla Model 3 battery cooling was much improved. To summarize that article, the main reasons are better heat transfer between the cells and the cooling tube (because the cells are now glued directly to the cooling tube),… Continue reading Tesla Model 3 Battery Can Transfer Twice The Heat Of Model S P100D

Elon Musk suspected sabotage when Tesla factory robots stopped working earlier this month

Joshua Lott | Getty Images

Engineer and tech entrepreneur Elon Musk of The Boring Company talks about constructing a high speed transit tunnel at Block 37 during a news conference on June 14, 2018 in Chicago, Illinois.

Elon Musk was up early on Saturday. He departed Los Angeles, where he runs SpaceX, his private rocket venture, and flew north in his white Gulfstream jet. Stopping in Silicon Valley, he picked up two engineers from Tesla, his electric-car company. They flew on to Reno, Nev., where they spent the day at Tesla's battery plant, the Gigafactory.

It might have been just another workday for Mr. Musk — a multistate jaunt to personally fix a drive-unit production line. But this was no ordinary morning. He was a brief night's sleep removed from one of his most consequential decisions: scrapping his plan to take Tesla private.

It was an abrupt about-face, and it capped a tumultuous two and a half weeks that began with a single tweet and wound up roiling markets, setting off regulatory alarms and raising questions about his judgment. Even by Mr. Musk's standards — this is a C.E.O. who believes Tesla is under attack by saboteurs, has a personal life playing out in the gossip blogs and is prone to fiery outbursts on Twitter — it has been a time of high intrigue.

“The reason Elon seems to attract drama is that he is so transparent, so open, in a way that can come back to bite him,” said Kimbal Musk, Mr. Musk's younger brother and a Tesla board member. “He doesn't know how to do it differently. It's just who he is.”

Mr. Musk, a brilliant but erratic billionaire, is the animating force behind Tesla, responsible for everything from its push into renewable energy to the design of the air vents in its newest electric car. His singular role gives him extraordinary influence over the fate of Tesla, its more than 40,000 employees and its investors.

Associates, including several people inside the company interviewed over the past week, portray him as a workaholic who zeroes in on the smallest details. His deep involvement suggests that the company can't do without him. Yet these days, it's not always clear that he knows what's best for Tesla.

More from The New York Times:

Google Attacked by Trump With Claim It Is Burying Conservative News

Silicon Valley Takes a (Careful) Step Toward Autonomous Flying

In a Shift in Driverless Strategy, Uber Deepens Its Partnership With Toyota

Even before taking Tesla investors on a roller-coaster ride, Mr. Musk was increasingly unpredictable, marketing flamethrowers online and dispatching a submarine to assist in a rescue in Thailand, then calling a critic of the gesture a pedophile. In an interview this month with The New York Times, Mr. Musk said he was physically exhausted and emotionally drained, causing some to question his fitness for the job.

Mr. Musk's personal life is no less chaotic. He was dating Grimes, the Canadian pop musician, but the two stopped following each other on social media last week, leading gossip blogs to speculate they had broken up. That followed a bizarre run-in with the rapper Azealia Banks, who intimated that Mr. Musk had written his going-private tweet while on acid. (He denied it.) Amid the fallout, he took to Twitter, posting cryptic messages about love and quoting T. S. Eliot.

And at the office, he is hardly a typical chief executive. Racing to resolve critical production issues, he can often be found on the factory floor, working to fix robots. At night, he sometimes sleeps under his desk. All the while, he has been confronting an exodus of senior employees, preparing to be interviewed by the Securities and Exchange Commission, and was working with Goldman Sachs and Saudi Arabia's sovereign wealth fund to take Tesla private — until he wasn't.

Some board members have been dismayed at Mr. Musk's behavior, according to people familiar with the directors' thinking, but no active search is underway for a replacement — although there have been fitful efforts to find a top lieutenant.

James Anderson, the head of the asset management firm Baillie Gifford, Tesla's biggest shareholder after Mr. Musk, said he still had faith in the 47-year-old chief executive, calling him a “visionary leader” who had unmatched technical expertise and remained “obsessive about the details.”

Yet Mr. Anderson said he had grown increasingly worried about Mr. Musk, believing that his volatile personal life and intense work ethic were taking a steep toll. “He is so demanding, so driven by the imperative to do something good for the world,” Mr. Anderson said. “You could always see something like this happening.”

'We feel like we are at war'

At 6:30 a.m. on Aug. 18, three robots in the paint shop at the Tesla factory in Fremont, Calif., started malfunctioning. The incident forced a production halt on the Model 3, the key to the company's future.

Made aware of the stoppage, Mr. Musk went to the factory and worked into the night. The problem was resolved, but Tesla reached a troubling conclusion: The robots had been infected with malware in an act of industrial sabotage. And though they could not prove it, executives suspected they knew the culprit: a rogue employee, working at the behest of short-sellers.

Tesla is among the most shorted stocks, meaning that hedge funds are betting against it and quick to note a missed production goal or cash shortfall. David Einhorn, the billionaire founder of Greenlight Capital, is in that camp. In a letter to investors last month detailing his argument, Mr. Einhorn wrote, “Elon Musk appears erratic and desperate.”

Mr. Musk believes that the short-sellers spread misinformation about the company, and perhaps much worse. In June, Mr. Musk accused an employee of sabotage that had slowed Model 3 production, and suggested short-sellers might be to blame.

Kimbal Musk, reflecting on the battles with short-sellers, said, “We feel like we are at war.”

Plenty of other companies face the wrath of short-sellers. The issue at Tesla seems to be that for Mr. Musk — who talks earnestly about weaning the world off fossil fuels with Tesla, and colonizing the solar system with SpaceX — these attacks are not just the cost of doing business. They are malicious and misguided efforts to derail his efforts to help humanity.

“Tesla is his baby,” said Deepak Ahuja, Tesla's chief financial officer. “He takes it extremely personally.”

But with Tesla now staying public, Mr. Musk will have to continue to contend with those who doubt his vision and are rooting for Tesla to fail.

The most difficult time

When Mr. Musk ceremonially unveiled the Model 3 last summer, he billed it as the first mass-market electric vehicle, and predicted monthly production of 20,000 by year's end. But in the final three months of 2017, just 2,425 were completed.

The delays were a result of what Mr. Musk called “manufacturing hell,” an inferno that has preoccupied him for much of the past year. “This has been the most difficult time for Tesla,” said JB Straubel, the company's chief technical officer. “We knew this was going to be the case, but it's been even harder than any of us expected.”

Some of the wounds were self-inflicted.

In preparing the assembly lines, Mr. Musk became convinced that the process should be close to fully automated, using robots rather than humans whenever possible. Doing so, he believed, could make cars move through the factory at one meter per second, 10 to 20 times the speed of existing lines.

So Tesla built a factory with hundreds of robots, many programmed to perform tasks that humans could easily do. One robot, which Mr. Musk nicknamed the “flufferbot,” was designed to simply place a sound-dampening piece of fiberglass atop the battery pack.

But the flufferbot never really worked. It would fail to pick up the fiberglass, or put it in the wrong place, frequently delaying production. It was eventually replaced by factory workers.

Mr. Musk has accepted responsibility for some of these missteps, occasionally with humor. In late June, he wore a T-shirt depicting a robot that passes butter. It was an inside joke, lampooning the notion of technology for technology's sake.

After the debacle, Mr. Musk tweeted: “Excessive automation at Tesla was a mistake. To be precise, my mistake. Humans are underrated.”

As the challenges have mounted, Mr. Musk has thrown himself into his work, spending hours each week walking factory floors, trying to diagnose and fix various problems on the assembly line.

“He demands personal accountability from the people that are closest to the machines,” Mr. Straubel said. “This freaks people out. They are worried that they wi..