New Gordon Murray Design technology cuts vehicle body weight in half

iStream Superlight reduces vehicle body weight by up to 50%

Applicable to all vehicle segments, the new chassis promises to be the lightest, strongest and safest platform for decades to come

Another new innovation, the iStream lightweight seat, achieves 30% weight saving over standard seat

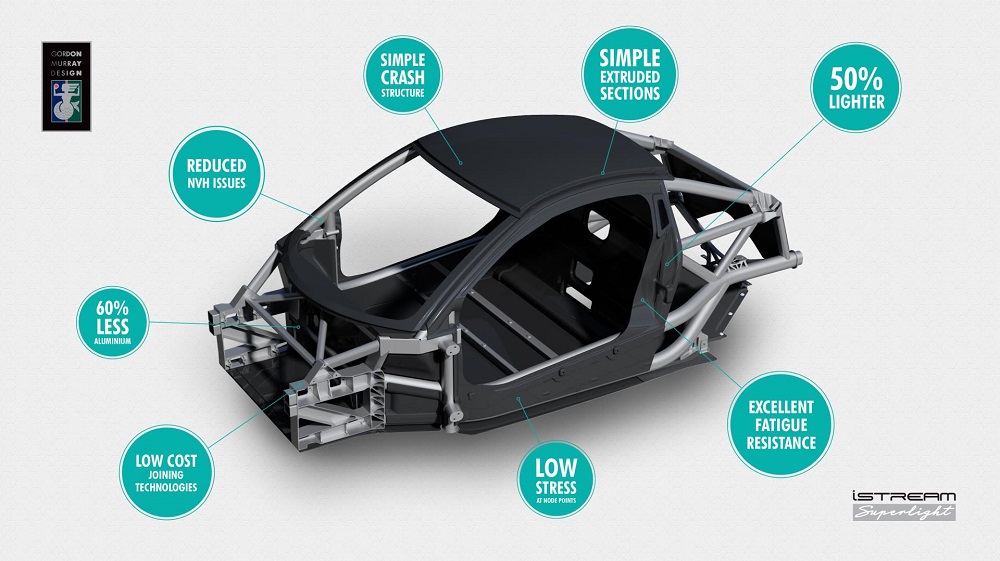

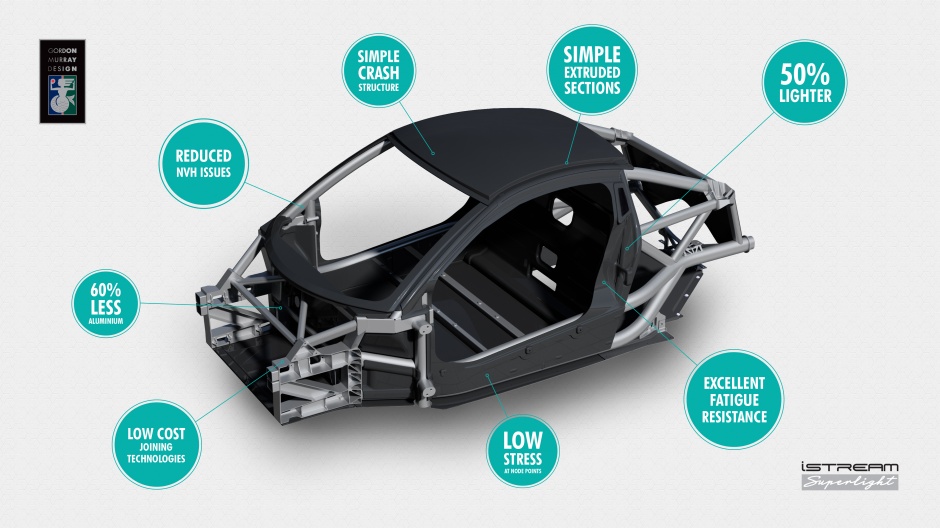

Dunsfold, UK: The world-leading British design and engineering company Gordon Murray Design has unveiled the latest version of its ground breaking iStream® automotive manufacturing system which revolutionises the way cars are manufactured. Combining a high-strength aluminium frame with advanced carbon fibre composite panels, iStream Superlight® brings Formula One-derived construction and technologies to mainstream car production.

The new process promises to usher in a new era of vehicle performance with the lightweight structure offering greater safety, lower emissions, improved handling, and enhanced durability. The new innovation not only delivers up to 50% weight reduction compared with a standard stamped-metal body, it also offers new levels of platform flexibility.

Due to the modular nature of the iStream Superlight chassis, the core platform can be adapted to suit every segment of vehicle from sports cars and ultra-efficient electric city cars to SUVs and light commercial vehicles. This adaptable formula ensures cost-effectiveness for manufacturers by avoiding the need for high capital investment and individual chassis designs for each model variant.

Professor Gordon Murray said: “The new iStream Superlight approach to vehicle manufacturing is a paradigm-shifting innovation for the global automotive industry. It is a breakthrough that will deliver the lightest chassis technology for decades to come. The Gordon Murray Design team has created a unique, adaptable and cost-effective way for manufacturers around the world to dramatically improve vehicle performance and efficiency.”

‘iStream Superlight’ employs a simple high-strength aluminium thin-wall tubular frame and honeycomb recycled carbon-composite chassis panels in place of the stamped metal used in most volume car production. Its lightweight design delivers a body-in-white structure delivering up to 50% of the weight of stamped metal, while achieving new levels of rigidity, durability and platform flexibility.

Key advantages of iStream Superlight**:

50% saving over conventional stamp steel BIW

Corrosion resistant properties exceed coated steel

Low weight aluminum frame can deliver a cost neutral BIW when compared to stamped steel

More efficient frame stiffness achieved for aluminum section through the use of carbon iPanels®

iStream lightweight seat

Gordon Murray Design has also revealed its new seat innovation – the iStream lightweight seat, which uses the same innovative materials, techniques and technologies as the iStream chassis.

This newly-developed seat incorporates glass or recycled carbon-fibre composite and a tubular frame to achieve dramatic weight savings. Compared to a typical vehicle seat, the iStream lightweight seat achieves a weight reduction of up to 30%. The iStream lightweight seat can be designed to suit all types of passenger vehicle.

While the design is aimed at weight saving in passenger cars, the new seat has the potential to benefit other passenger transportation sectors. From aerospace to rail, the patented design delivers new levels of lightweight and low tooling costs.

*** Key advantages of iStream lightweight seat:

30% weight saving vs conventional modern seat

iStream lightweight composite structure (glass or carbon)

Full four-way adjustment and fold-flat mode

T.43 iStream Superlight sports car

During Gordon Murray Design’s One Formula event in November 2017, which celebrated Gordon Murray’s 50 years of car design, a new company was announced – Gordon Murray Automotive (GMA) – alongside the official opening of the GMA premises at Dunsfold in Surrey.

GMA also announced a new licensing model to complement its existing iStream technology licensing programme. The new licencing approach focuses on licensing automotive platforms alongside existing iStream licences. The T.43 sports car is the first platform and product designed for licence or sale.

The T.43 sports car utilises iStream Superlight and is designed to be an everyday usable coupe with not only exceptional performance capabilities, but also class leading ergonomics, visibility, and cargo capacity. The T.43 introduces new levels of lightweight, torsional stiffness, and durability.

T.43 sports car specifications:

Power to weight ratio: 259 bhp per tonne

Power: 220 bhp

Weight: 850 kg

Engine: 1.5 litre three-cylinder turbo

Transmission: Six-speed manual

Length – Rolling chassis: 3,640 mm

Width: 1,750 mm

Height – Rolling chassis: 1,240 mm

Wheelbase – Rolling chassis: 2,500 mm

The new iStream Superlight structure is the output of a collaborative research project part-funded by the Innovate UK framework. Led by Gordon Murray Design, the consortium includes Bentley Motor Company, Brunel University London, Constellium, and Innoval Technology. The iStream seat also benefitted from collaborative research with Gordon Murray and Formaplex Limited pooling resources for the duration of a 12-month study.

-Ends-

Notes to editors

Gordon Murray Design will exhibit its iStream Superlight body and iStream lightweight seat at the LCV 2018 show on 12-13 September 2018 on stand C3-100.

About Gordon Murray Design

Gordon Murray Design is a visionary design and engineering company with its headquarters in Shalford in Surrey, plus R&D and manufacturing facilities in Dunsfold. It was established in 2007 with a focus on developing an innovative and disruptive manufacturing technology trademarked iStream, and has since built a global reputation as one of the finest automotive design teams in the world.

The company’s unique approach and truly creative thinking enables Gordon Murray Design to deliver complete car programmes in a highly efficient and innovative way from concept and design, through to prototype and development for production.

About Gordon Murray Automotive

Gordon Murray Automotive was launched in November 2017. Cars built by the new business will be based on a new version of Gordon Murray Design’s revolutionary iStream production system. The company will also be able to manufacture vehicles on a low-volume basis for external customers.

Gordon Murray Automotive forms part of a new corporate organisation for the engineering group, and is positioned as a sister company to Gordon Murray Design.

About iStream

Rather than the traditional method of combining hundreds of panels of stamped metal, iStream uses tubular metal with 10 – 15 structural composite panels. iStream Superlight is the ultimate automotive lightweighting technology as it maximises the iStream approach by using cored honeycomb carbon fibre composite and an aluminium frame to save almost 50% in weight against a standard stamped metal chassis.

iStream is an acronym for iS = Stabilised; T = Tube; R = Reinforced; E = Exo-frame; A = Advanced; M = Manufacturing.

About iStream Superlight

** Advantages of iStream Superlight

50% saving over conventional stamped steel BIW

High degree of flexibility in optimising aluminium section shapes to ensure structural efficiency

Corrosion resistant properties exceed coated steel

Cold metal transfer welding reduces distortion and manufacturing time

Low weight aluminium frame can deliver a cost neutral BIW when compared to stamped steel

Delivers new levels of efficient body quality

Aluminium saving vs conventional aluminium BIW

More efficient frame stiffness achieved for aluminium section through use of carbon iPanels

Low cost, high recycled content aluminium alloys

Re-cycled carbon fibre

Aluminium iFrame® protected from external damage

All hard points (i.e. suspension, steering etc.) are carried by the aluminium iFrame

Carbon sandwich panel cycle time of 100 seconds

About iStream lightweight seat

*** Advantages of the iStream lightweight seat

iStream lightweight composite structure (glass or carbon)

Full four-way adjustment and fold-flat mode

30% weight saving vs conventional modern seat

Satisfies all applicable European automotive requirements (UN ECE), including luggage retention requirements

Ultra-low tooling and developments costs

Low part count

Simple, high-speed assembly

Suitable for low and high-volume applications

Can achieve low seating position

Excellent package performance

Anti-submarining design

Competitive piece cost

Patent protected

PR contacts

For further information, images or comment, contact PFPR Communications:

Ed Callow, Account Director

Tel: +44 (0)1622 766520

Mob: +44 (0)7732 088337

ed.callow@pfpr.com

Jon Visscher, Associate Director

Tel: +44 (0)1622 776680

Mob: +44 (0)7816 906794

jon.visscher@pfpr.com

Sarah Smith, Communications Officer at Gordon Murray Design

Tel: +44 (0)1483 484700

enquiries@gordonmurraydesign.com

DOWNLOADSDownload Release